The manufacturing of bags involves a process called Blown Film Extrusion. This technique is employed to create not just garbage bags but also other products such as vapor barriers, bread bags, grocery bags, and numerous other items intended for retail packaging.

In this process, plastic pellets are introduced into the machine hopper of a device known as an Extruder. The plastic is moved forward by a rotating screw within a heated barrel, where it is heated and softened due to friction and heat. The plastic is then pushed upward through a circular die to form a hollow tube shape.

The Blown Film Extrusion process is continuous. After exiting the die, the tube is expanded using air and compressed by the take-off or nip rollers. The volume of air in the bubble, the speed of the nip rollers, and the output rate of the extruder collectively determine the thickness and width of the film.

The tube or “web” of film is then consistently rolled up by take-off rollers. Alternatively, the web of film can be directly fed into a bag-machine in an in-line process. To create the bag, the tube is heat-sealed across its width to form the bottom and cut further up the tube to create the opening.

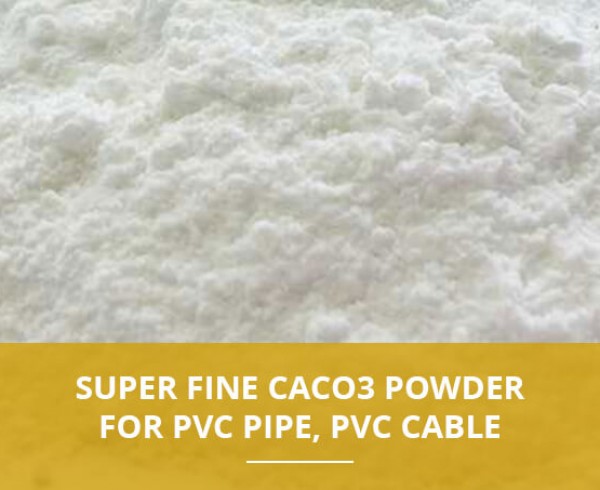

PE filler masterbatch, composed of PE resin, CaCO3, and additional additives such as processing aids and dispersion agents, is engineered to optimize production efficiency while enhancing the impact resistance, heat resistance, surface hardness, tensile strength, and ductility of final products.

This masterbatch finds its application in various products, particularly in injection molding and blown film processes for items such as shopping bags and T-shirt bags. In the food packaging industry, PE filler masterbatch serves as an alternative to conventional PE resins. It’s also utilized in the production of PP woven bags and laminated films. By using PE filler masterbatch, manufacturers can not only reduce costs but also improve the stiffness, flexibility, and thermal resistance of their products.

At GCC Group, we’re proud to have a team of experts specializing in the plastics industry. Our commitment is to provide high-quality and cost-effective solutions for plastic manufacturers. Learn more about the features of our PE filler masterbatch below:

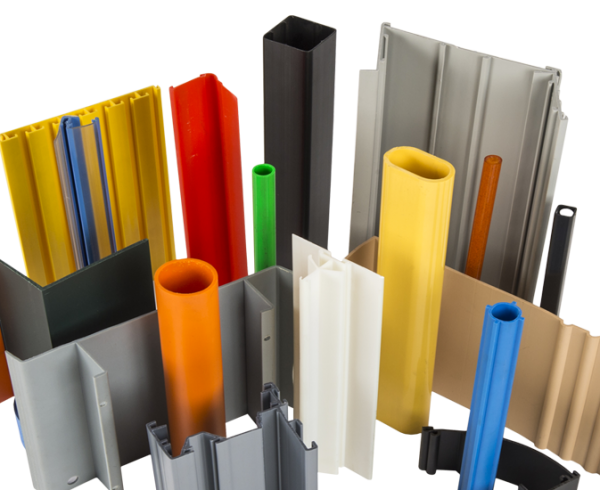

Plastic retail : rolled bags, food packaging, shopping, garbage bags.

Agriculture: Mulching film, greenhouse films, silage films, plant bags

Construction plastic sheeting: vapor barrier, waterproof barrier, protective wrap, roofing underlayment.

Others:

- Packaging: either 25 kg PP/PE bags or jumbo bags, depending on requirements.

- Storage: a cool and dry condition to maintain their quality.

- Delivery: by road or by sea, as per the agreement.

- Additives: processing aids, coupling agent, dispersion additives

- Processing Temperature: The optimal range is 140°C – 280°C.

- Appearance (Surface Color): white, smooth, 3x3mm.