The process of extrusion blow molding starts with the creation of a parison or tube using a die, similar to those employed in the production of plastic pipes. Blow molding is the preferred method for producing plastic bottles, including milk jugs, shampoo containers, bleach bottles, and various other products commonly found on store shelves.

In this process, plastic pellets are loaded into the machine’s hopper, also known as a blow molder. These pellets are then pushed forward by a screw inside a heated barrel, where the heat and friction work together to soften the plastic. The softened plastic is then extruded downwards through a circular die, resulting in a hollow plastic tube known as a “parison.”

Subsequently, the parison is secured within a hollow mold and inflated from within. The internal air pressure causes the parison to expand against the mold surface, taking the shape of the mold’s interior as the plastic cools. The mold then opens, releasing the plastic bottle, which can then be moved along to further stages such as trimming, printing, and filling.

In addition to extrusion blow molding, other techniques include Stretch Blow and Injection Blow molding. Extrusion blow molding is versatile and can process various plastics, such as HDPE, PP, PET, and LDPE.

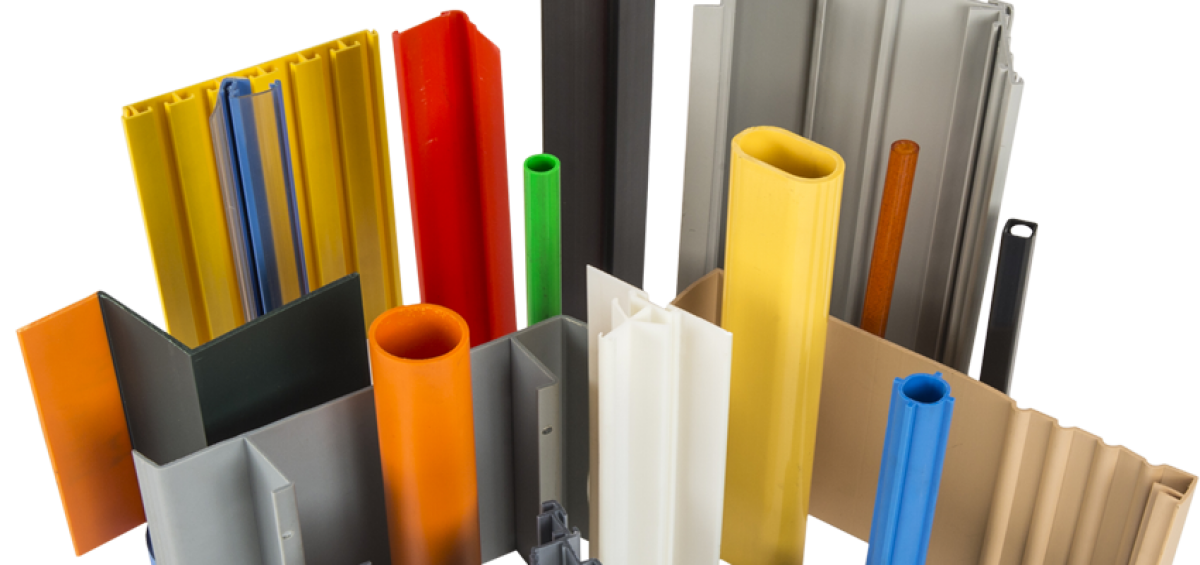

Pipes, profile extrusion : Plastic straws, Plastic pipes, Plastic Sheets, Plastic profile

Raffia Textile : Jumbo bags, Cereals bags, Cement bags, Cattle feed bags

Non woven fabric : non-woven bags, medical protective items, car ceiling, Geotextile

Others:

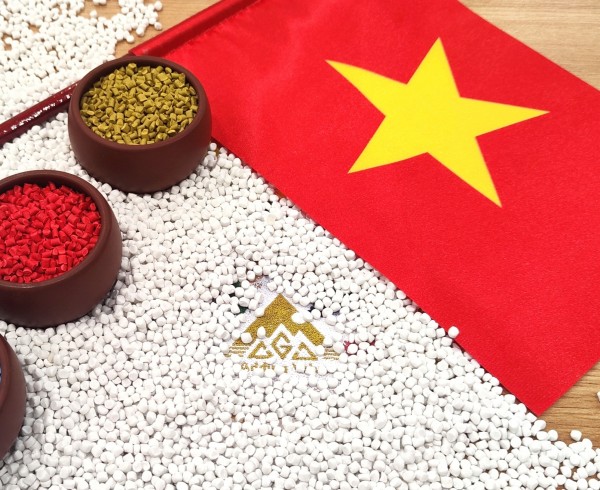

- Packaging: either 25 kg PP/PE bags or jumbo bags, depending on requirements.

- Storage: a cool and dry condition to maintain their quality.

- Delivery: by road or by sea, as per the agreement.

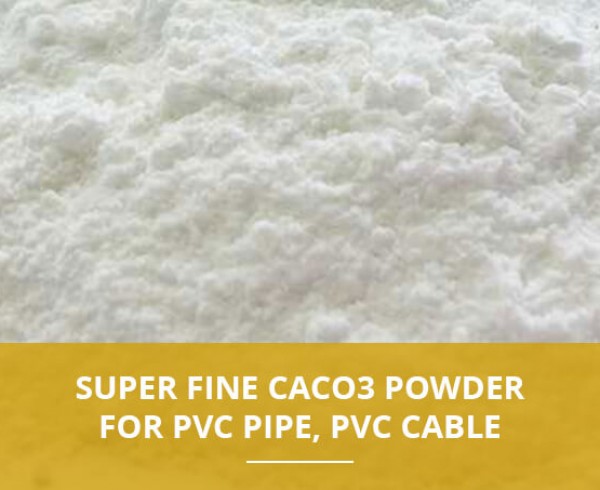

- Additives: processing aids, coupling agent, dispersion additives

- Processing Temperature: The optimal range is 140°C – 280°C.

- Appearance (Surface Color): white, smooth, 3x3mm.