Injection molding is a process utilized for creating components from thermoplastic materials. In this method, molten plastic is injected under high pressure into a mold, which is shaped inversely to the desired product. The mold is crafted by a mold maker, or toolmaker, typically using metal—either steel or aluminum—and is precision-machined to incorporate the specific features of the intended part. Injection molding is a popular method for producing a diverse range of parts, from the tiniest elements to entire car body panels. It is the most prevalent method of production, with everyday items such as bottle caps and outdoor furniture often being produced this way.

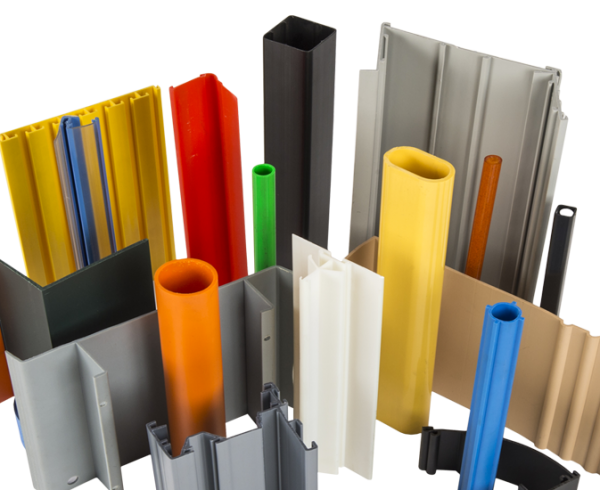

Among the thermoplastics frequently used in this process are polystyrene (low cost, but lacking in strength and durability), ABS or acrylonitrile butadiene styrene (a co-polymer or blend of compounds utilized in products ranging from toy parts to electronics casings), nylon (known for its chemical resistance, heat resistance, toughness, and flexibility, often used in items like combs), polypropylene (tough and flexible, used for containers), polyethylene, and polyvinyl chloride or PVC. PVC is more commonly found in extrusions and is used for products like pipes, window frames, or as insulation on wiring, where it is made flexible through the addition of a significant proportion of plasticizer

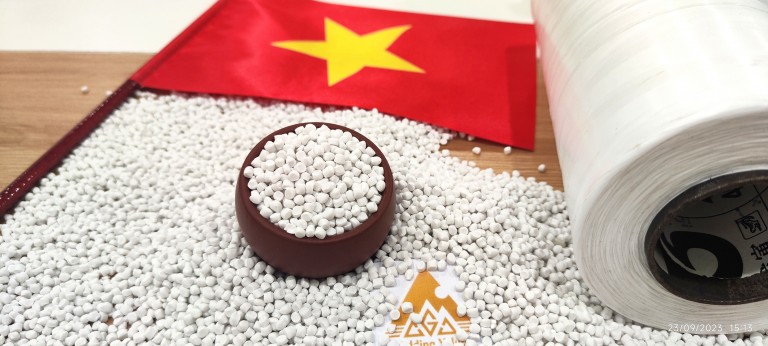

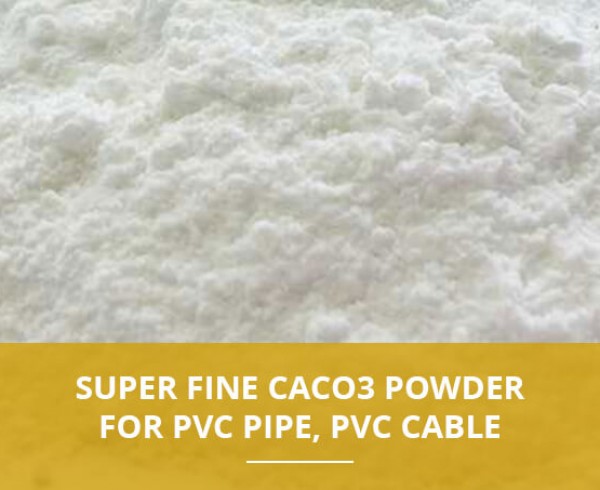

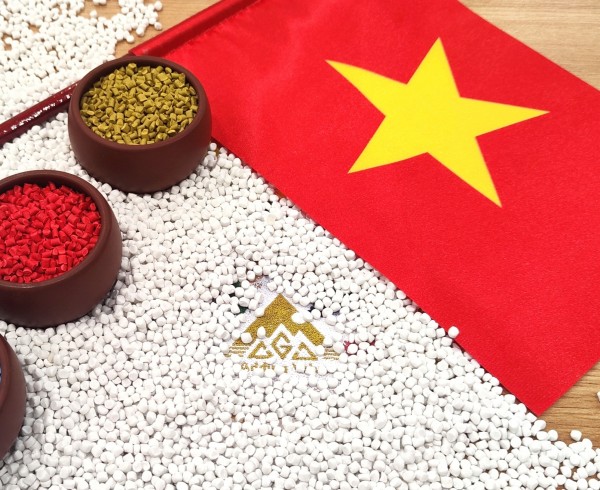

PP filler masterbatch, consisting of calcium carbonate (CaCO3), polypropylene (PP) resin, and various other plastic additives, is widely used in the plastics industry for its cost-saving and productivity-enhancing properties.

PP filler masterbatch also holds a vital role in processes such as extrusion, blow film, and injection molding. Due to its rapid cooling property, it boosts extruder productivity and reduces processing times. Additionally, PP fillers elevate the mechanical properties of the end product, mitigate shrinkage, increase hardness and clarity, and most importantly, help manufacturers in reducing production costs.

Household appliances: Plastic Containers, toys, blender, vacuum.

Electronic devices: computer plastic case, camera components, phone charger, plastic case

Automotive components : Grille radiator, car dashboard, car door, bumpers

Electric components : Electric generator plastic case, office machien gears, cooling fan, electronic parts trays

Others:

- Packaging: either 25 kg PP/PE bags or jumbo bags, depending on requirements.

- Storage: a cool and dry condition to maintain their quality.

- Delivery: by road or by sea, as per the agreement.

- Additives: processing aids, coupling agent, dispersion additives

- Processing Temperature: The optimal range is 140°C – 280°C.

- Appearance (Surface Color): white, smooth, 3x3mm.