Related Post

-

ADVANTAGES: Boost in extruder production; Enhancement of bubble stability; Improvement in the film’s physical and mechanical properties; Facilitation of welding; Substantial reduction in raw material costs; Anti-blocking feature; Prevention of screws, heads, and dies fromRead more

-

The process of extrusion blow molding starts with the creation of a parison or tube using a die, similar to those employed in the production of plastic pipes. Blow molding is the preferred method forRead more

-

Injection molding is a process utilized for creating components from thermoplastic materials. In this method, molten plastic is injected under high pressure into a mold, which is shaped inversely to the desired product. The moldRead more

-

Thermoforming refers to the heating of a thermoplastic sheet until it reaches a pliable state, and then stretching and shaping it over or into a one-sided mold. The process begins with the sheet being securedRead more

-

The manufacturing of bags involves a process called Blown Film Extrusion. This technique is employed to create not just garbage bags but also other products such as vapor barriers, bread bags, grocery bags, and numerousRead more

-

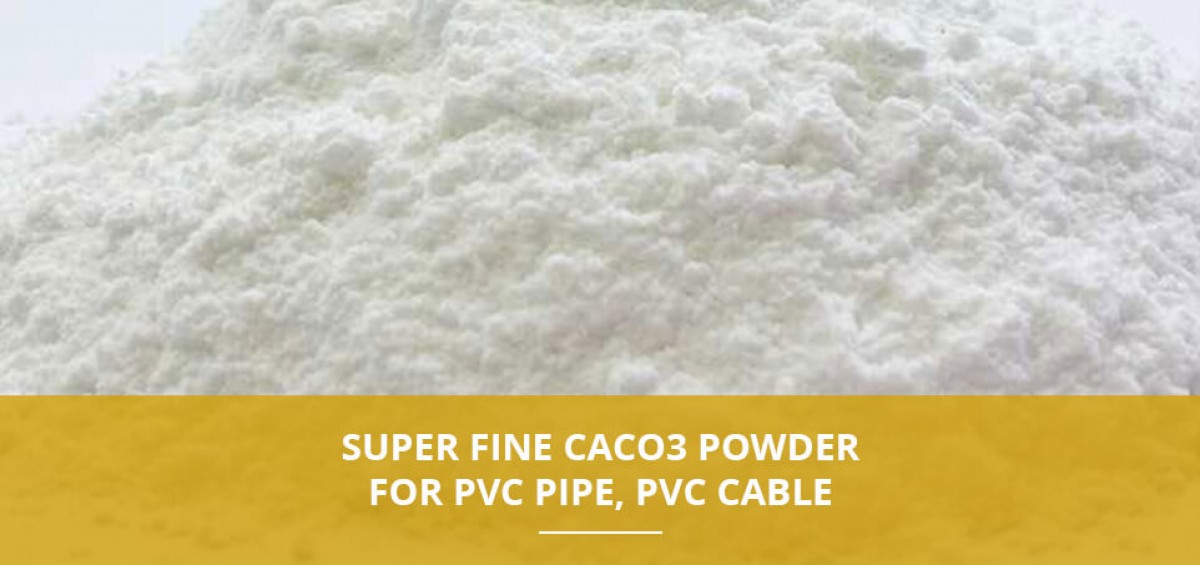

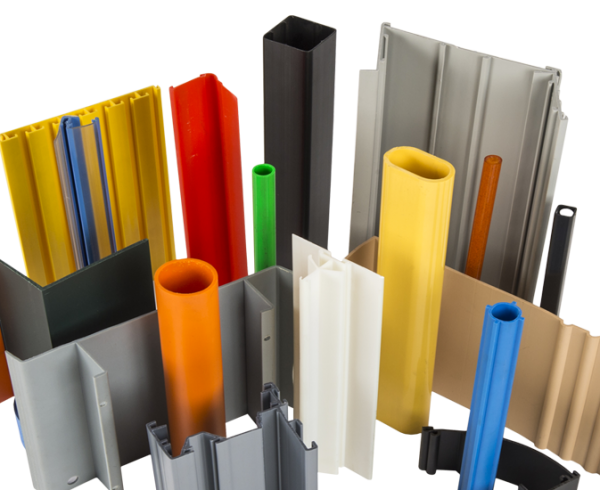

Filler masterbatch plays a crucial role in the production of plastic goods. GCC Group’s Filler masterbatch is crafted from a blend of calcium carbonate (CaCO3), plastic resin granules, and plastic additives, tailored to meet theRead more

-

Vietnam is considered a country with diverse mineral resources with more than 5000 mines of 60 types of minerals. In which, some types have important reserves such as bauxite (672.1 million tons), apatite (0.778 millionRead more