- Thermoforming refers to the heating of a thermoplastic sheet until it reaches a pliable state, and then stretching and shaping it over or into a one-sided mold. The process begins with the sheet being secured in a holding device and heated through convection or radiant heat within an oven until it softens. Next, the sheet is positioned horizontally above a mold and is either pressed into or stretched over the mold using a combination of vacuum pressure, air pressure, or mechanical force. The pliable sheet conforms to the mold’s shape and is retained in position until it solidifies upon cooling. Subsequently, surplus material is trimmed off, and the finished part is then extracted. The remnants can be ground down, combined with fresh plastic, and reshaped into thermoplastic sheets.

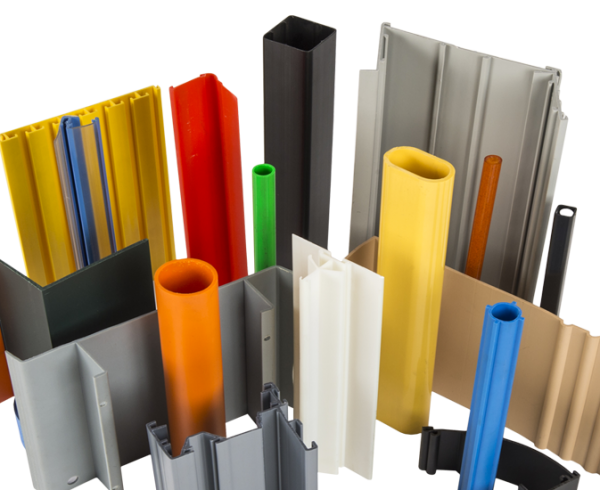

- Thermoforming has a range of applications, including food packaging, and extends to products like plastic toys, aircraft windscreens, and cafeteria trays. Sheets with a thickness less than 0.060 inches are generally used for rigid or disposable packaging, while sheets thicker than 0.120 inches are used for cosmetic permanent surfaces on automobiles, shower enclosures, and electronic equipment. The process accommodates various thermoplastic materials such as:

- – Low Density Polyethylene (LDPE)

- – High Density Polyethylene (HDPE)

- – Polypropylene (PP)

- – Polystyrene (PS)

- – Polyvinyl Chloride (PVC)

- – Acrylic (PMMA)

- – Acrylonitrile Butadiene Styrene (ABS)

- – Cellulose Acetate

- The thermoforming process employs different techniques to mold the thermoplastic sheet to the desired shape, which include:

- – Vacuum Forming: A vacuum is generated between the mold cavity and the thermoplastic sheet. This vacuum pressure (typically 14 psi) compels the sheet to mold into the shape of the mold.

- – Pressure Forming: Besides using a vacuum under the sheet, air pressure (typically 50 psi, but up to 100 psi) is exerted on the backside of the sheet to help shape it onto the mold. This extra force allows for the forming of thicker sheets and the creation of more detailed textures, undercuts, and sharp corners.

– Mechanical Forming: The thermoplastic sheet is mechanically pushed into or around the mold through direct contact. Generally, a core plug is used to press the sheet into the mold cavity, forcing it into the desired shape

Food packaging: Egg trays, vegetable containers, ice cube trays, food trays

Manufacturing industry: components trays, plastic pallet, phone components trays, printer components trays

Household appliances: Toys blister packaging, vegetable pots, medicine blister pack, plastic knife trays

Others:

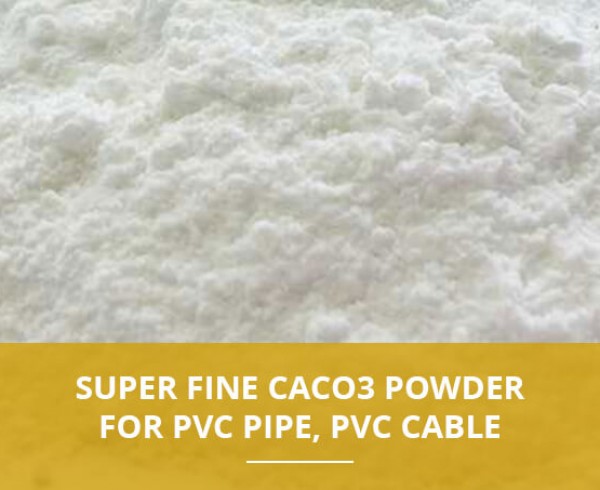

- Packaging: either 25 kg PP/PE bags or jumbo bags, depending on requirements.

- Storage: a cool and dry condition to maintain their quality.

- Delivery: by road or by sea, as per the agreement.

- Additives: processing aids, coupling agent, dispersion additives

- Processing Temperature: The optimal range is 140°C – 280°C.

- Appearance (Surface Color): white, smooth, 3x3mm.